Breaking the Mold at American Tool and Mold

American Tool and Mold is a pioneer in the tool and die industry in more ways than one.

对于初学者来说, it is owned and run by CEO Emilia Giannakopoulos, making it one of the very few woman-owned companies in the industry.

And American Tool and Mold has evolved into a full-service mold builder and molder with 160 employees. Its services include designing and manufacturing complex, 精度, multi-cavity molds for the plastic injection molding industry. It also provides thin-wall, 堆栈, 热流道, unscrewing and two-shot, high-cavitation molds for consumer packaging, specialty closures and medical industries. In 2023 it added a rapid prototyping division called ATM-X.

The Clearwater, Fla. company added bt365体育娱乐 graphite milling machines with automation and Mitsubishi wire 电火花s about two years ago.

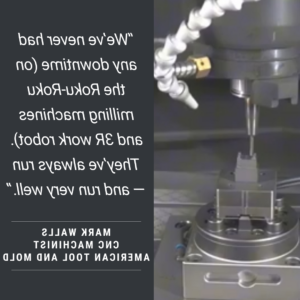

As part of a multi-million dollar capital equipment investment, ATM purchased two Roku-Roku HC-658-II vertical graphite milling cells, each with a System 3R WorkPartner 1+ robot with 280 stations to automate electrode production and maximize unattended time.

As part of a multi-million dollar capital equipment investment, ATM purchased two Roku-Roku HC-658-II vertical graphite milling cells, each with a System 3R WorkPartner 1+ robot with 280 stations to automate electrode production and maximize unattended time.

“So we’re averaging somewhere about 100 to 150 hours, maybe even a little bit more than that some weeks, of unattended time, which was huge,” said ATM Senior Project Manager Steve Cochenour.

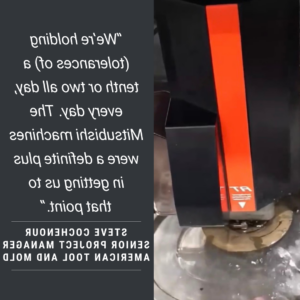

ATM also added two Mitsubishi MV2400-R wire 电火花 machines to increase throughput and capacity.

Cochenour said that when the company was in the market for a new wire 电火花 machine, they talked to “the big three” in the wire 电火花 market and sent each material and specs.

“It was a difficult material to work with. It was called Elmax and we asked each to do a real tight-tolerance hole through 10 inches of material,他说. “Those machines from Mitsubishi were able to hold the test cuts within the tolerances that we were looking for. And as far as I know, (bt365体育娱乐) was the only one able to hold the tolerances.”